Products

Contact Us

No 153, Huandong Er Road, Fengjing Industry Park, Fengjing Town, Jingshan District, Shanghai

TEC

The following referenced documents are indispensable for the production of product;

ASTM E8, Standard Test Methods for Tension testing of Metallic Materials ;

ASTM E18, Standard Test Methods for Rockwell Hardness of Metallic Materials ;

ASTM E140, Standard Hardness Conversion Tables for Metals — Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness and Scleroscope Hardness ;

ASTM E384, Standard Test Method for Knoop and Vickers Hardness of Materials ;

ASTM B3-95, Materials & Performance Standard for Solid Copper Conductors ;

ASTM B8-95, Concentric-Lay-Stranded Copper Conductors, Materials & Performance Standard for Stranded Copper Conductors.

File Download

Product Details

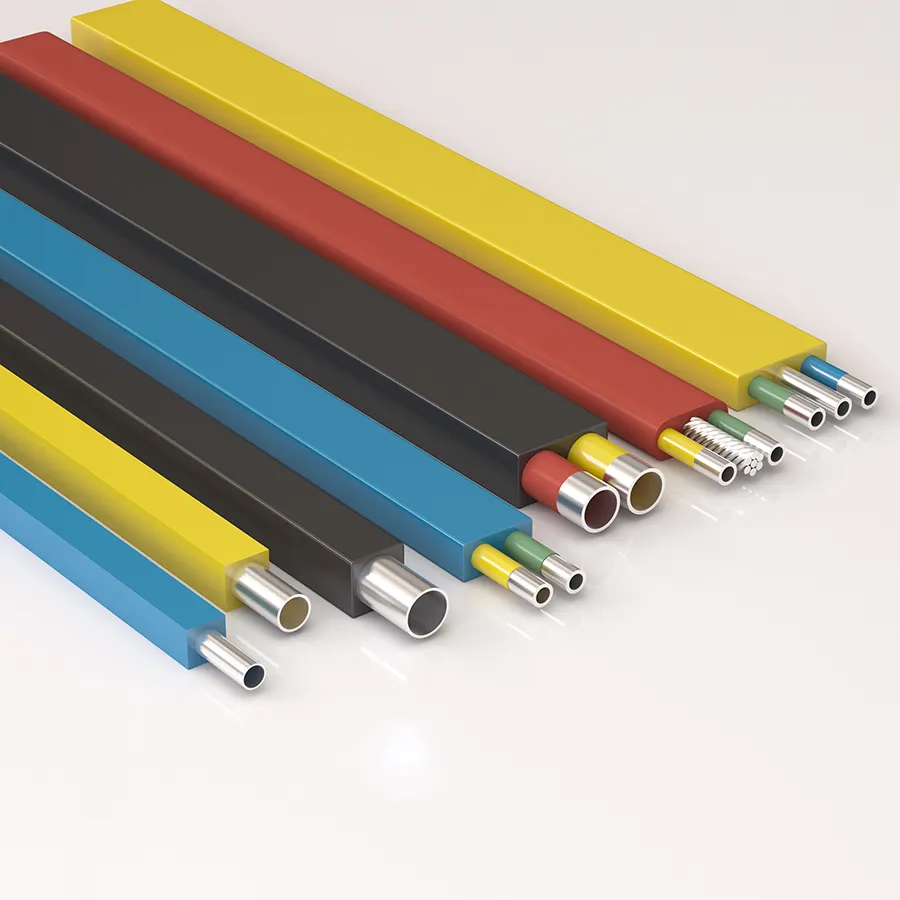

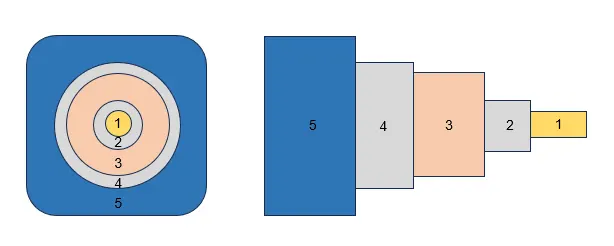

| No. | Component | Purpose | Material | Capabilities | |

| 1 | Cable | Conductor | Conduct electrical power and signal | Solid or strand copper conductor | Solid or strand |

| 2 | Insulation | Insulated electrical power/signal | ECTFE, FEP,PFA | FEP | |

| 3 | Filler Layer | Provide support for insulated conductor & fill annular space | PP, FEP,PFA | PP | |

| 4 | Armor | Provide mechanical and environmental protection to insulated cable | 316L, 825 | 1/4" X 0.049" | |

| 5 | Encapsulation | Provide mechanical and abrasive protection to armor | PP, TPV, PVDF,ETFE, FEP | PP, TPV, PVDF,ETFE, FEP | |

Selection of Tube

| Grade | O.D. | W.T. | Yield Strength | Tensile Strength | Collapse Strength |

| ( in ) | ( in ) | (psi) | (psi) | (psi) | |

| TP316L | 1/4" | 0.028" | 90000 | 120000 | 16000 |

| 1/4" | 0.035" | 19800 | |||

| 1/4" | 0.049" | 26200 | |||

| N08825 | 1/4" | 0.028" | 100000 | 125000 | 17000 |

| 1/4" | 0.035" | 20900 | |||

| 1/4" | 0.049" | 27600 |

Notes:The calculated value of collapse strength is based on the min yield strength.

Selection of Cable

| Filler | PP | PP | FEP | PFA | |

| Insulation | FEP | ETFE | FEP | PFA | |

| Max. Applicable Temperature | 150 | 150 | 200 | 260 | |

| Conductor Size | O.D. | Max. Resistance (/km) | |

| AWG | Solid Core | 7 Strands | 20℃ |

| 16 | 1.29 | 13.5 | |

| 18 | 1.02 | 7/0.39 | 23 |

There are multiple configuration options for copper conductors

1- Size: 12, 14, 16,18, 20, 22AWG etc;

2- Type: solid core or stranded conductor;

3- Material: bare copper, tin-plated, silver-plated and other copper conductor.

Selection of Encapsolation, Insulation and Filler Materials

| Material | Maximum Temperature Rating (F/C) | Inhibited Brine Completion & Packer Fluids | Oil/Diesel Completion & Packer Fluids | Abrasion Resistance |

| Polyamide 11 (Nylon 11, Rilsan 11) | 200/95 | N/R | Good | Excellent |

| Polypropylene (PP) | 300/150 | Excellent | N/R | Good |

| TPR/TPV/TPE (Santoprene) | 300/150 | Good | Good | Good |

| EPDM/ Propylene Copolymer | 260/130 | Excellent | N/R | Poor |

| Polyvinylidene Fluoride (kynar PVDF) | 280/140 | Good | Excellent | Excellent |

| ECTFE (Halar ECTFE) | 300/150 | N/R | Excellent | Good |

| ETFE (Tefzel ETFE) | 310/155 | Excellent | Excellent | Excellent |

| FEP (Teflon FEP) | 400/205 | Excellent | Excellent | Good |

| PFA Teflon PFA) | 500/260 | Excellent | Excellent | Good |

keyword:

Related Products